MATERIALS

Choose materials that have less impact on humans, nature and animals.

From day one, we have chosen to work with quality materials to create pieces that not only stand the test of time, but also age beautifully.

To walk on the bright side means choosing high quality materials with the least possible environmental impact, ensuring animal welfare and sourcing only recycled synthetic materials.

By 2024

81%

of ba&sh items were made from a minimum of 70% certified or less environmentally impactful materials such as linen, raffia or hemp*

78%

of the materials used in our collections will be certified

* With the exception of recycled fibres, which achieve a rate of 40%

By 2024

88%

of cotton will be organic or recycled

85%

of viscose will be alternative (LENZING™, LENZING™ Lyocell, TENCEL™ Modal) or made from wood pulp sourced from sustainably managed forests

72%

of wool comes from certified sources (guaranteeing animal welfare and sustainable pasture management, recycled or certified organic)

55%

of synthetic materials are recycled

Our target:

80% certified materials by the end of 2028

Raw materials account for 58% of our carbon footprint. Hence, they constitute an essential lever for reducing our impact.

To reduce our greenhouse gas emissions and help preserve biodiversity, we select our materials with care, always choosing the best possible option, such as organic or recycled fibres, or certified materials that guarantee animal welfare and sustainable pasture management, based on labels with the highest standards.

And when the best option is not possible - due to lack of supply, for instance - we select the next best alternative. For example, the distinct style and fit of certain pieces can only be achieved using synthetic materials. In such cases, we use recycled synthetic fibres wherever possible (see polyester section).

Our commitments

concerning materials

ba&sh committed to preserving forests

ba&sh has partnered with the environmental not-for-profit Canopy and is a signatory to both the CanopyStyle Initiative and Pack4Good programmes.

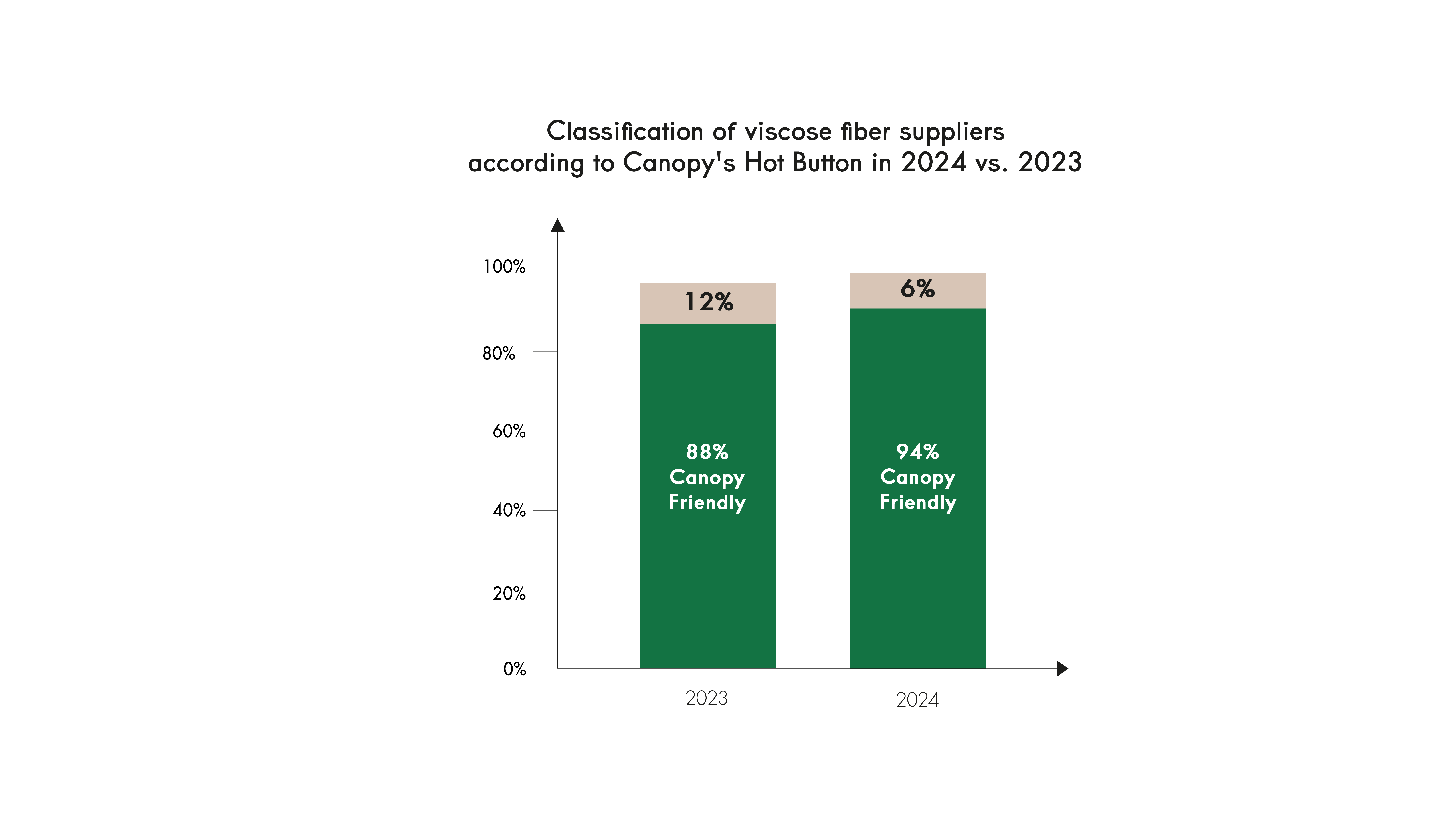

Since the 2021 Winter collection, ba&sh works together with Canopy to identify viscose suppliers in our supply chain each season. By guaranteeing that no ba&sh product made from viscose contributes to deforestation, this project contributes to our goal of preserving forests. It reflects our commitment to making enlightened choices in selecting our materials: always prioritizing the best possible option.

94%

of viscose sourced from viscose producers classified as "Canopy-friendly" in 2024 according to the Canopy’s Hot Button (in quantities produced).

The Canopy Hot Button is the leading fiber sourcing analysis tool for the fashion industry that focuses on forest preservation. Viscose producers labeled “Canopy-friendly” have been rated “Dark Green,” “Green-Dark Green,” or “Green.” This refers to producers who, through their practices, do not source cellulose fibers from ancient and endangered forests.

2025 target

100% of the viscose fibers used in our collections come from “Canopy-friendly” viscose suppliers

ANIMAL WELFARE

ba&sh has committed to never using materials that result from the suffering or killing of animals.

Furthermore, we actively support agricultural methods that prioritize animal well-being. Consequently, we have phased out several materials from our collections over the years, including some that featured in several of our best-selling items.

We work closely with NGO Four Paws - an animal welfare nonprofit - to continually improve our animal welfare policy.

2028 target

70% of materials and animal fibers certified according to standards that include animal welfare and sustainable pasture management criteria, or are organic or recycled

A ban on fur: ba&sh is a member of the Fur Free Retailer Program

A ban on exotic leather, feathers, down and angora

A ban on mulesing - a cruel and commonly practiced mutilation of lambs - mainly from Australia. ba&sh is a signatory to the Brand Letter of Intent initiated by Four Paws.

100% recycled cashmere

ba&sh is also supporting sheep farms in their transition towards more regenerative farming practices

ba&sh committed to regenerative agriculture

ba&sh is committed to developing and funding regenerative agriculture projects. In Uruguay, 3 sheep farms are currently transitioning towards regenerative farming practices, equivalent to 8 hectares in the process of regeneration.

Regenerative agriculture has the potential to fundamentally transform farming: regenerating soils, protecting biodiversity, eliminating synthetic inputs, ensuring social equity & improving the economic situation of farmers as well as animal welfare.

2028 target

Increase the proportion of regenerative wool in our collections

Frequently asked questions

Raw materials account for 58% of our carbon footprint. Hence, they constitute an essential lever for reducing our impact. To reduce our greenhouse gas emissions and help preserve biodiversity, we select our materials with care, always choosing the best possible option, such as organic or recycled fibres, or certified materials that guarantee animal welfare and sustainable pasture management, based on labels with the highest standards.

And when the best option is not possible - due to lack of supply, for instance - we select the next best alternative.

To find out more, visit the “Materials” section of our website.

Since 2019, ba&sh has assessed its carbon footprint yearly, using the GHG Protocol methodology across all its direct and indirect activities.

In 2024, ba&sh's activities generated 65,576 tonnes of CO₂e, equivalent to driving around the world 7,528 times or flying 37,020 times between Paris and New York.

Between 2023 and 2024, ba&sh reduced its carbon footprint by 5%.

This reduction has been made possible thanks to 4 key action levers: increasing the proportion of certified materials in our collections, reducing air transport, cutting our production volumes and switching to less carbon-intensive, renewable energy for our infrastructures (sales outlets, warehouse and head office).

ba&sh has established a strict social compliance policy, which is appended to the General Terms and Conditions signed by all suppliers.

We require direct suppliers to conduct a social audit every 2 years. We recognise only the most demanding international standards: BSCI, SMETA, WCA, ICS. Suppliers are assessed on social performance criteria including: working conditions, remuneration, decent working hours, health and safety, rights to freedom of association and collective bargaining, environmental protection... Following the audit, ba&sh works together with suppliers in implementing corrective measures to address any non-compliance.

Since 2023, ba&sh has been a member of Amfori, a business association that helps companies improving working conditions in their supply chains. As of this year, we will also be conducting environmental audits in our denim laundries.

In 2024, 94% of our tier 1 production sites had been audited.

Our goal is to have 100% of our Tier 1 production sites audited by 2025, and 30% of our Tier 2 sites by 2028.

To find out more, visit the "Partners" section of our website.

In 2024, 53% of our production came from medium-haul import regions (Europe, North Africa, Turkey) while 47% came from long-haul import regions (China, India). Between 2021 and 2024, 7% of our production was relocated from Asia to Europe and North Africa.

We have no intention of stopping here: by 2028, we aim to have 60% of our production sourced from medium-haul import regions (Europe, North Africa, Turkey) and 40% from long-haul import regions (China, India).

To find out more, visit the "Partners" section of our website or read our sustainability report.

B Corp™ certification is based on an assessment of a company's overall impact in seven key areas: Mission & Stakeholder Governance, Climate Action, Human Rights, Fair Labor, Justice, Equity, Diversity & Inclusion, Environmental Management & Circularity and Public Affairs & Collective Action. This assessment is conducted using a comprehensive questionnaire which the company must complete itself, providing documents to support each claim.

To achieve certification, a company must score over 80 points. The evaluation process is demanding and rigorous. In the case of ba&sh, it lasted 18 months.

As a B Corp™, we’re part of a global community of businesses that meet high standards of social and environmental impact.

Our animal welfare policy has recently been updated in line with the recommendations of animal welfare nonprofit Four Paws, who has also reviewed our policy. This document is appended to our General Terms and Conditions, which are signed by all suppliers.

In concrete terms:

- ba&sh is committed to increasing its share of certified animal raw materials (RWS, RMS, GRS) to 70% by 2028. The RWS, RMS and RAS labels guarantee animal welfare and sustainable pasture management at certified suppliers. The GRS label guarantees the recycled origin of recycled textile fibres.

- ba&sh has banned the use of fur as a member of the Fur-Free Retailer Program.

- ba&sh prohibits the use of exotic leather (e.g. crocodile, snake, etc.).

- ba&sh has banned the use of down and feathers.

- ba&sh has banned the use of angora.

- ba&sh prohibits the practice of mulesing as a signatory to the Brand Letter of Intent initiated by Four Paws.

- ba&sh only uses recycled cashmere.

To find out more, visit the "Materials" section of our website or read our sustainability report.