A love story

Ten years. Ten years of exchanges, phone calls, meetings, projects carried out together. If you feel like you're reading a love story, it's because the bond between us and our suppliers is one! It is these years of collaboration that have enabled us to continually improve the quality of our products, and it is the result of a relationship of trust that allows us today to go further, by taking them on board with us in the sustainable and ambitious transformation project that we are carrying out.

Supplier Code of Conduct

Each year, all of our suppliers sign our code of conduct and commit to the fundamental ethical principles it outlines. Our suppliers must also ensure that their own subcontractors comply with these principles, failing which we reserve the right to terminate any business relationship.

A social audits programme

ba&sh has a policy of social audits. We only recognise the most stringent methodologies: BSCI, SMETA SEDEX, WCA or ICS. The social audit must be repeated every 2 years. When non-conformities are identified during the audit, ba&sh carries out follow-up work with suppliers, via corrective action plans.

In August 2021, ba&sh joined a social compliance initiative.

We joined the Business Social Compliance Initiative (BSCI), an organisation dedicated entirely to social compliance, with the aim of improving working conditions in companies' international supply chains. Supplier mapping, early detection of problems, auditing, corrective action and training.

We intend to go even further. From 2023 we will also conduct environmental audits. We will start with the denim laundering facilities.

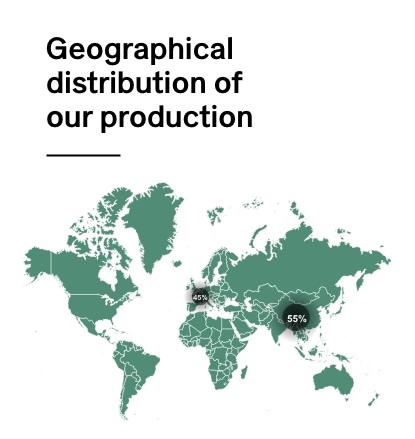

60% of our production is carried out in Asia, between China and India. We produce clothing in mainly cotton, viscose and polyester, which are raw materials that come from these regions.

40% of our production is takes place between Europe (30%) and north Africa. This is where most of our accessories & knitwear are produced using local know-how.

In 2022, 68% of our tier 1 production sites will be audited, i.e. audited by an independent third party according to BSCI, SMETA SEDEX, WCA or ICS methodologies and less than 2 years old.

The target is to reach 100% by the end of 2023.

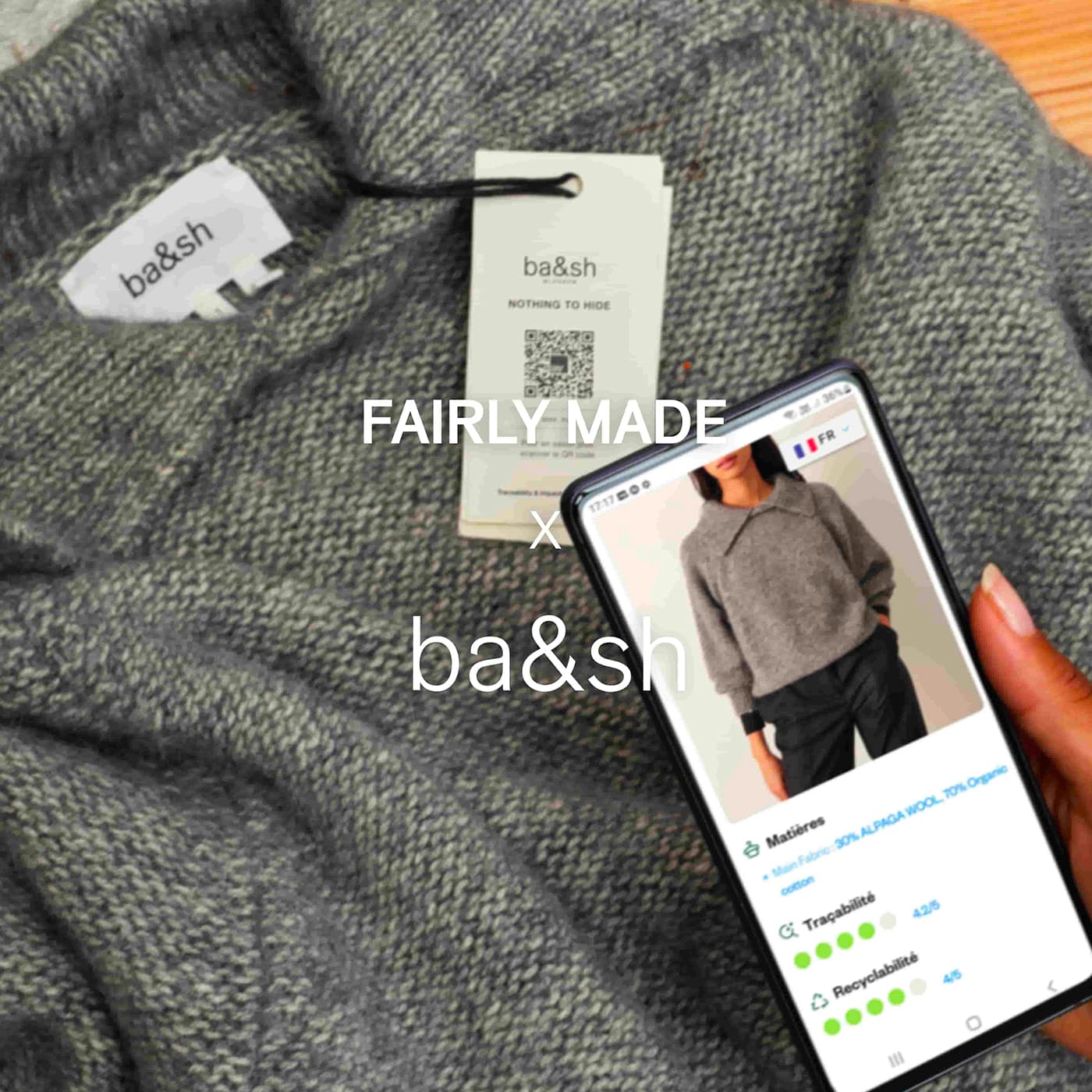

Fairly Made x ba&sh

We are continuing our commitment that began in 2020 to achieve a high level of traceability in our supply chains and to provide our customers with even greater transparency on our products. In spring 2022, we partnered with a product traceability and impact measurement solution called Fairly Made.

The Fairly Made x ba&sh collaboration has allowed us to take these steps towards better traceability: 30 products in the Winter 2022 collection, 100 products in Summer 2023 and 300 traceable products in the Winter 2023 collection.

This tool measures the traceability of products and the kilometers traveled thanks to 3 indicators: carbon footprint, freshwater euthropisation and energy consumption. From 2024, 100% of our references subject to the AGEC law will be traced.

The 6 pillars of our commitment

Frequently asked questions

The production of raw materials is ba&sh's main area of concern in terms of greenhouse gas emissions and pressure on biodiversity.

To reduce this impact, ba&sh gives preference to organically grown materials, certified materials that guarantee animal welfare and the sustainable management of pastures, recycled fibres and viscose made from wood pulp from sustainably managed forests.

In 2022 production, 57% of materials were certified. By 2025, this figure is projected to have reached 100% (except for alpaca, for which the target has been set for 2027).

We have defined a framework to monitor and improve social performance in our supply chain.

Each partner must commit to our supplier code of conduct and comply with a number of ethical principles.

We conduct social audits of our entire supplier base. If non-conformities are identified, we support our suppliers in implementing corrective action plans to contribute as much as possible to the rapid and sustainable transformation of our industry.

Since August 2021, ba&sh is also a member of BSCI, a social compliance initiative. This tool provides a framework for monitoring and improving social performance in our supply chain: supplier mapping, early detection of problems, auditing, corrective actions and training. The aim is to protect workers' rights and improve their working conditions.

Our shopping bags and parcel boxes are made from 80% and 100% recycled paper and are FSC-certified. They are 100% recyclable.

In 2022, 93% of packaging used at ba&sh was made from at least 50% recycled paper.

In 2022, 87% of plastic packaging was made from at least 30% recycled plastic. While 12% of packaging was still made from virgin plastic in 2022, ba&sh aims to use 0% virgin plastic by the end of 2023.

ba&sh is also in the process of implementing a circular and reusable packaging solution. After receiving an order, the packaging used to send your parcel can be returned by post free of charge. When empty, it can be folded into a letter format! This packaging reduces greenhouse gas emissions by more than 80% compared to 100% recycled and 100% recyclable packaging.