Experts in the field

In 2022, 69% of items contained at least 70% certified materials (organic, recycled, animal welfare guarantees) or less impacting materials such as linen, raffia or hemp.*

In 2022 (Autumn-Winter 2022, Spring-Summer 2023, ready-to-wear):

- 50% of the cotton is organically grown.

- 65% of certified viscose is milled from wood pulp from sustainably managed forests.

- 55% of wool comes from a certified chain that guarantees animal welfare and sustainable pasture management, or is recycled or organically grown.

- 40% of the polyester is recycled.

*With the exception of recycled fibres, the threshold is 40%.

Our commitments on materials

Raw materials are our biggest area of impact. To reduce our greenhouse gas emissions and limit our impact on biodiversity, we favour fibres from organic farming, certified channels that guarantee animal wellbeing and sustainable management of pastures, recycled fibres, or viscose made from wood pulp from sustainably managed forests. ba&sh carefully selects the most demanding labels.

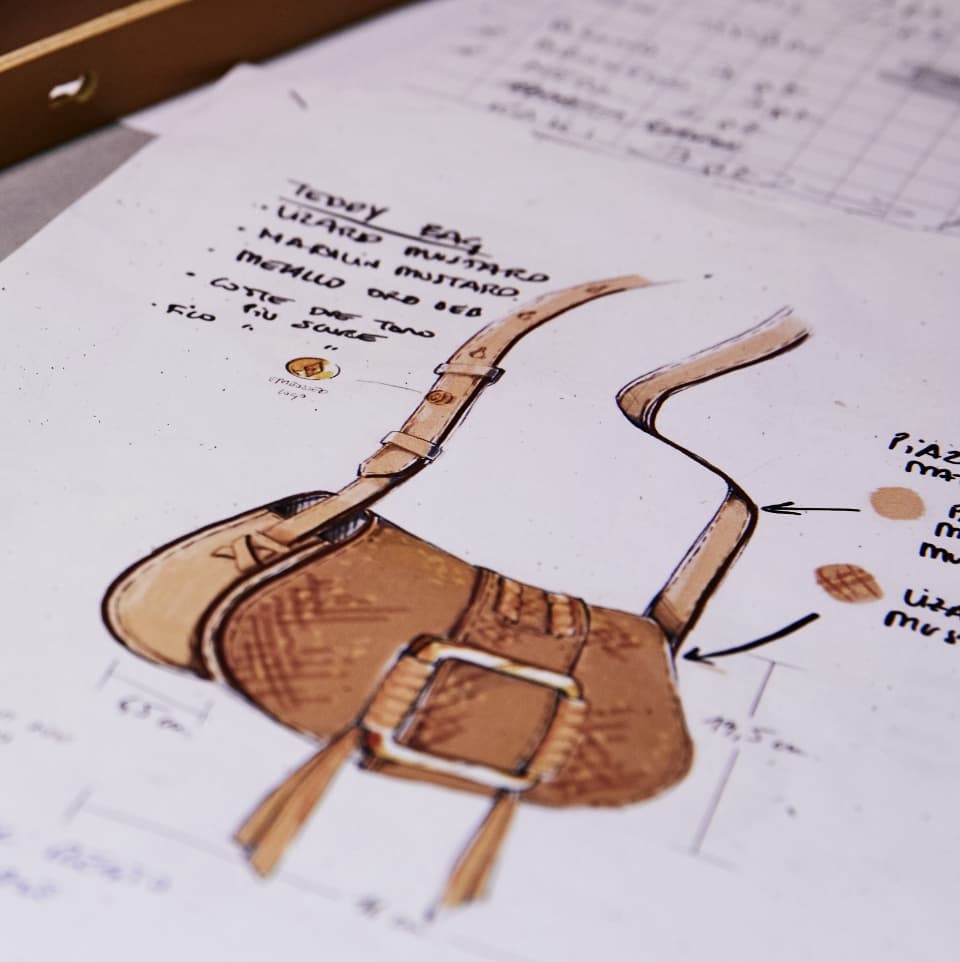

ba&sh, between creation and tradition

Bringing together our creative drive and century-old craft techniques, finding the balance between technical innovation, artistic expression and know-how: thanks to a close relationship with our craftsmen and women, we invent new ways of enhancing the most beautiful leathers every season, with the strictest respect for the level of quality expected at each key stage: cutting, trimming, assembling, mounting, sewing and applying dyes.

The ba&sh jewellery

ba&sh is also involved in the creation of ethical jewellery. The collections are made of solid recycled 925 silver (on which a thin layer of gold is melted for the gold versions), and produced in a Thai workshop renowned for its fine craftsmanship and mastery of its patinas. As far as diamonds are concerned, ba&sh has chosen to align itself with the Kimberley Process, which guarantees the supply of stones that do not come from illegal or conflict-financed activities. But because the mines are not inexhaustible, the objective remains to favour, for the years to come, jewellery collections made from synthetic diamonds.

The Cactus Teddy. Our it-bag has been redesigned using cactus as an alternative to leather

You already know Teddy, our simple and urban wallet-on-chain. Now discover its alternative in an innovative material made from cactus, Desserto®. Significantly less polluting to produce than leather and most of its alternatives, this material comes from cactus cultivation, and is combined on this version with a recycled acetate buckle and a recycled cotton lining.

Desserto®, but what for?

- To produce something better, with less: three cactus "leaves" are enough to create one metre of Desserto®.

- To limit the pressure on the use of resources: only the mature leaves of the plant are cut, without damaging the rest.

- To take advantage of its resilience: cacti can grow in very poor soils, and are able to thrive in areas where nothing else grows.

ba&sh signs the CanopyStyle Initiative

ba&sh has partnered with the NGO Canopy - an environmental non-profit organisation that works with over 800 companies and partners - and joined the CanopyStyle and Pack4Good programmes to take action for the preservation of endangered forests.

Canopy works with leading industry players and their suppliers to implement solutions to protect ancient forests. This partnership allows ba&sh to control the traceability of its viscose and transform its supply chain at source.

In the Winter 2022 collection, 92% (in terms of quantities produced) of viscose fibres come from viscose producers classified as "green shirt" * according to the Canopy Hot Button.

Objective 2024: 100% of the viscose fibres used in our collections will come from "Canopy-friendly" suppliers.

*The viscose producer does not present a risk of deforestation.

Animal welfare

Our animal welfare policy which is based on the Five Fundamental Freedoms and now also on the 5 areas, according to the NGO Four Paws in its 2021 report on animal welfare in the textile industry.ba&sh excludes exotic leather from its sourcing and only sources hides that are by-products of the meat industry.

ba&sh is working to strengthen traceability in its leather supply chains. As such, we have recently joined the Leather Working Group (www.leatherworkinggroup.com) Traceability and Animal Welfare Working Group.

For animal fibres (wool, mohair, alpaca), wherever possible, ba&sh sources from certified supply chains that guarantee animal welfare and sustainable pasture management. For example, the RWS label for wool strictly prohibits mulesing and other ablation practices. For cashmere, we only use recycled fibres.

The 6 pillars of our commitment

Frequently asked questions

The production of raw materials is ba&sh's main area of concern in terms of greenhouse gas emissions and pressure on biodiversity.

To reduce this impact, ba&sh gives preference to organically grown materials, certified materials that guarantee animal welfare and the sustainable management of pastures, recycled fibres and viscose made from wood pulp from sustainably managed forests.

In 2022 production, 57% of materials were certified. By 2025, this figure is projected to have reached 100% (except for alpaca, for which the target has been set for 2027).

We have defined a framework to monitor and improve social performance in our supply chain.

Each partner must commit to our supplier code of conduct and comply with a number of ethical principles.

We conduct social audits of our entire supplier base. If non-conformities are identified, we support our suppliers in implementing corrective action plans to contribute as much as possible to the rapid and sustainable transformation of our industry.

Since August 2021, ba&sh is also a member of BSCI, a social compliance initiative. This tool provides a framework for monitoring and improving social performance in our supply chain: supplier mapping, early detection of problems, auditing, corrective actions and training. The aim is to protect workers' rights and improve their working conditions.

Our shopping bags and parcel boxes are made from 80% and 100% recycled paper and are FSC-certified. They are 100% recyclable.

In 2022, 93% of packaging used at ba&sh was made from at least 50% recycled paper.

In 2022, 87% of plastic packaging was made from at least 30% recycled plastic. While 12% of packaging was still made from virgin plastic in 2022, ba&sh aims to use 0% virgin plastic by the end of 2023.

ba&sh is also in the process of implementing a circular and reusable packaging solution. After receiving an order, the packaging used to send your parcel can be returned by post free of charge. When empty, it can be folded into a letter format! This packaging reduces greenhouse gas emissions by more than 80% compared to 100% recycled and 100% recyclable packaging.